Condition Monitoring

for Predictive Maintenance

For CONDITION MONITORING, drive and status data are recorded periodically or continuously in order to optimise the operational safety and efficiency of machines and plants. CONDITION MONITORING can provide major information for PREDICTIVE MAINTENANCE. The objective is to maintain machines and plants proactively, to reduce downtimes and to increase the efficiency of the entire plant.

Advantages for our customers:

- Detection and avoidance of impermissible operating states at an early stage

- Status-oriented maintenance replaces time-based maintenance

- Plannable machinery and plant downtimes based on real drive and process data

- Reduction of service and material costs

- Longer service life of components and machine

- Increase in system availability

- Avoidance of unplanned downtimes

- Plannable and cost-optimised repair

The intelligent drive with condition monitoring for predictive maintenance

The INDUSTRIAL INTERNET of THINGS (IIoT) focuses on internet usage in industrial processes and procedures. IIoT aims at increasing the operational efficiency, reducing costs and speeding up processes. Sensors and sensor data playing a central role provide the basis for CONDITION MONITORING and PREDICTIVE MAINTENANCE.

- Condition monitoring solutions for predictive maintenance systems integrated into the frequency inverter

- System is IIoT/Industry 4.0 READY!

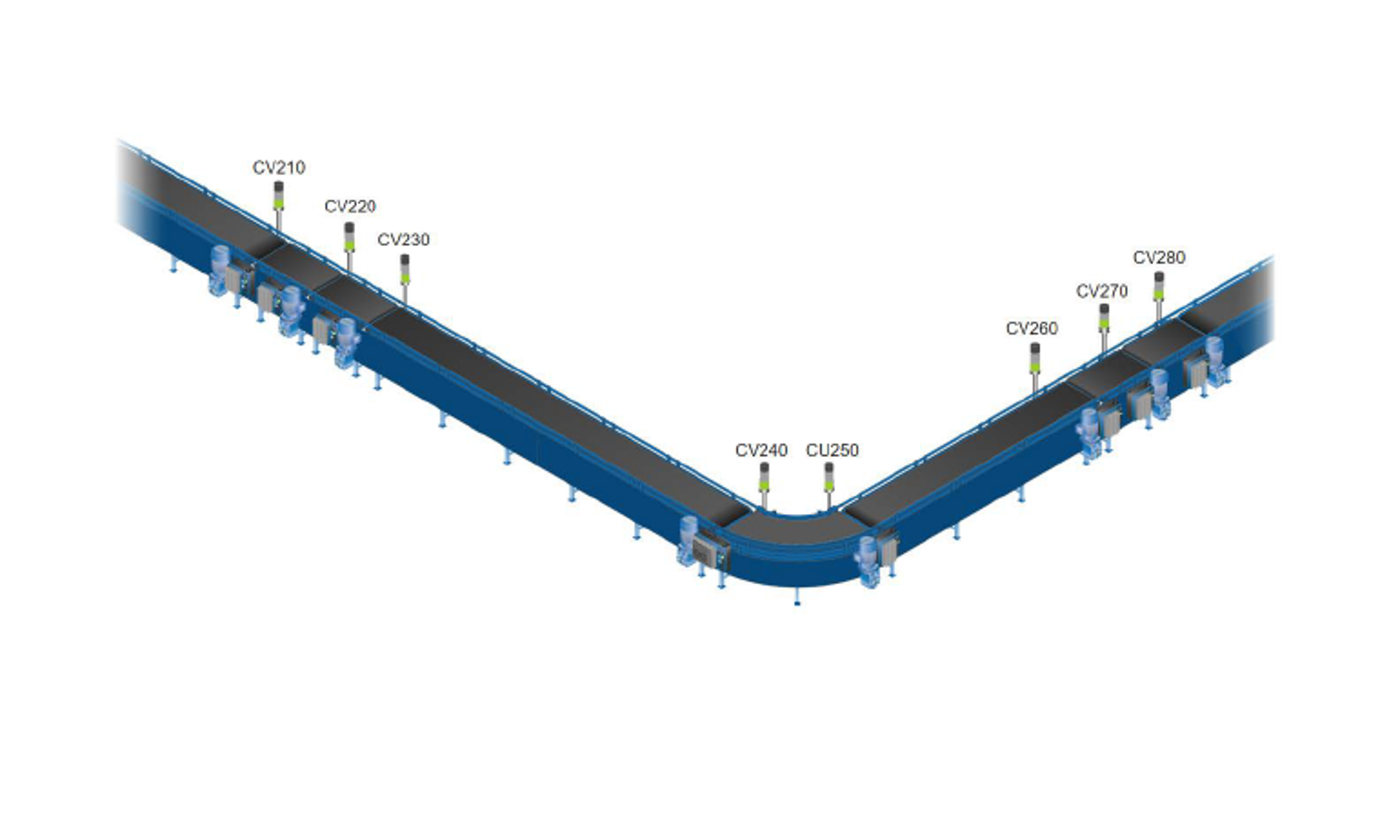

- Available for decentralised and control cabinet solutions

Sensors

- Virtual sensors – the PLC can calculate information such as the optimal oil change time

- Interface for digital/analogue sensors

Communication interfaces

Threshold values or general status information can be communicated externally (via normal Industrial Ethernet dialects)

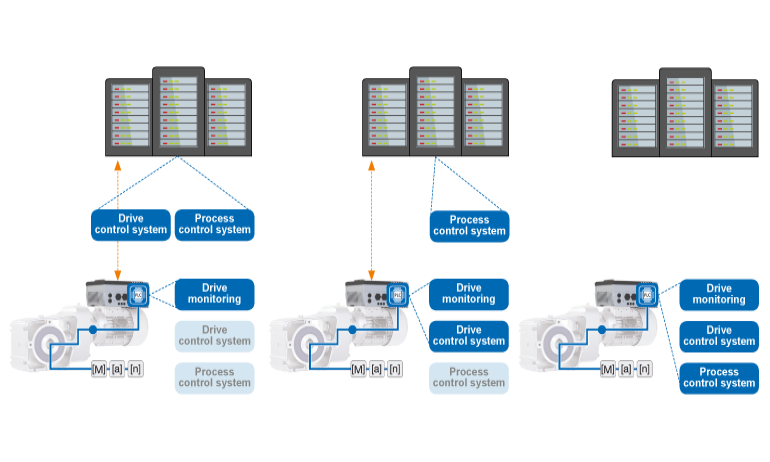

Integrated PLC

- Local pre-processing of data with the integrated PLC

- Pre-processing of threshold values

Information from condition monitoring can be transferred to predictive maintenance.

Drive-based approach

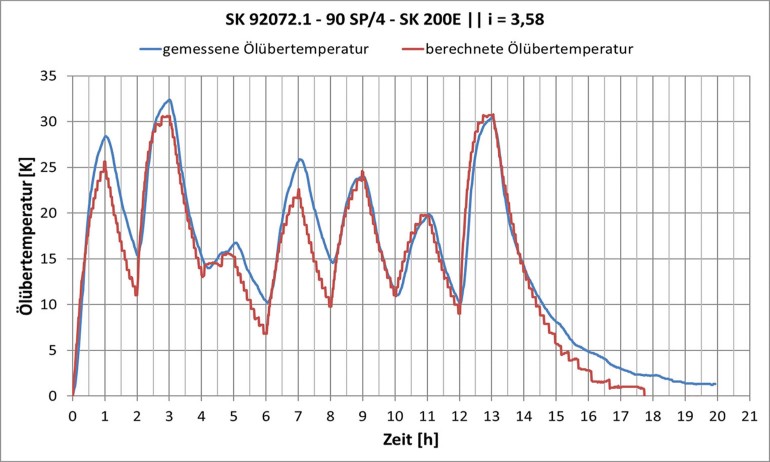

- Sensorless determination of the optimal oil change time based on virtual oil temperature

- Pre-processing of drive data in the integrated PLC

- Offering the data to the customer via all common interfaces

- Gear unit parameters and specific operational parameters make it possible to precisely calculate the oil change time.

- The NORD solution is based on the fact that the oil temperature is a key factor for oil ageing in gear units.

- A hardware temperature sensor is not needed because virtual sensors calculate the current oil temperature continuously by way of drive-specific parameters.

- The existing frequency inverter from NORD is used as an evaluation unit: The algorithm runs in the internal PLC.

- Integrated PLC available for all NORD frequency inverters and motor starters

- Runs drive-related functions

- Integrates drive-related actuators and sensors

- Parameter access

- Access to Industrial Ethernet or field bus data

- Implementation of application-specific functions

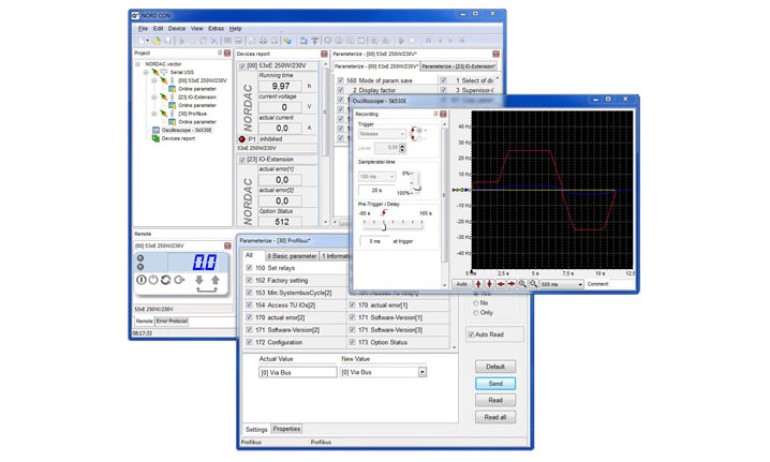

NORDCON APP

Dashboard-based visualisation for drive monitoring and fault diagnosis, Parameterisation with Help function and rapid access to parameters, Oscilloscope function

more information

NORDCON SOFTWARE

User-friendly parameterisation and programming of several drives, PLC editor according to IEC 61131-3, supporting Structured Text (ST), Instruction List (IL) and PLCopen Motion Control library Multi-axis access via Ethernet tunnelling

Download NORDCON