News –

NORD drive systems with precise control ensure smooth parcel distribution

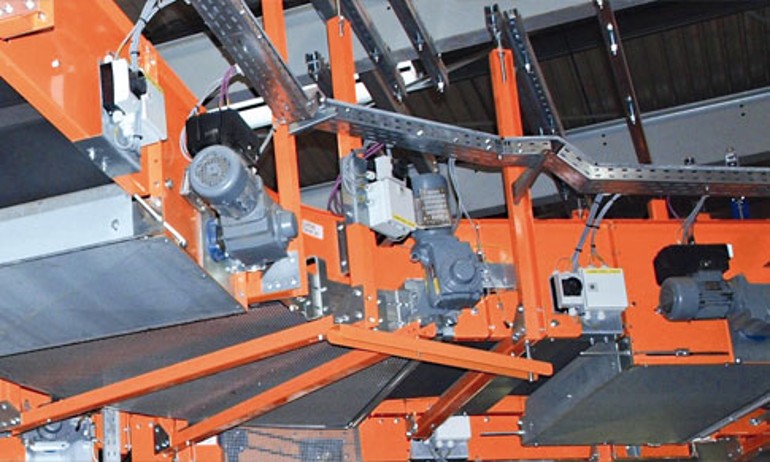

NORD provides large parcel distribution centres with drive technology, e.g. Chronopost, a company near Paris. 1,000 NORD drives with decentralised drive electronics will be installed for Chronopost's belt conveyors.

Bargteheide, 2017-05-16

Drive units from NORD DRIVESYSTEMS ensure low maintenance and long service life due to their durable, wear-free gearing. This well thought out modular system of gear motors with high overload capacity eliminates the need for a large number of versions, despite the high amount of drive units that are part of the conveyor system.

The tracking and tracing procedures at Chronopost require precise control and synchronisation. For this purpose, the drive systems are equipped with motor-mounted frequency inverters , installed directly on the motor terminal box. These inverters with plug-in technology form a prewired unit with the gear motor .

The drive systems are extremely robust thanks to a starting torque of up to 400 % and a typical overload capacity of 200 % for 5 seconds. The inverters communicate with the PLC via Profibus DP. In case of backlogs, the conveyor chain can be slowed down. Thus, downtimes can be prevented.