News –

Drives 4.0: Status monitoring with the Cloud

NORD DRIVESYSTEMS develops Industry 4.0-ready concepts and economical solutions for status monitoring of drives based on virtual sensors. This includes making status data of drives available in the Cloud in real time.

Bargteheide, 2018-02-06

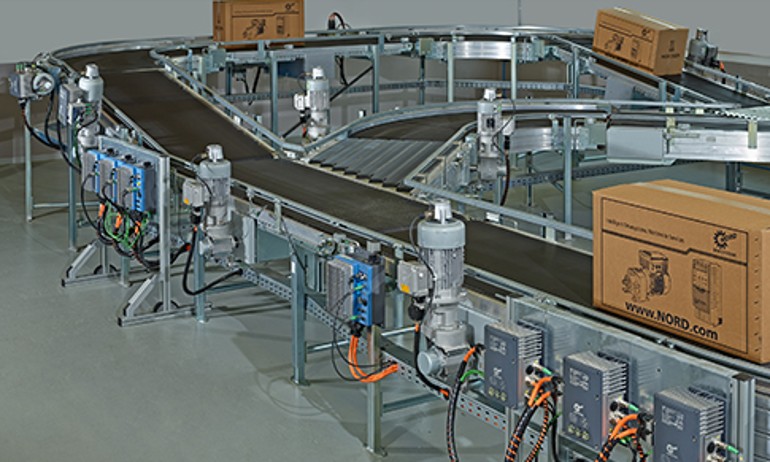

In their application test centre in Bargteheide, NORD tested web-based monitoring of drive shafts in a networked structure with standard interfaces and components. For this, the frequency inverters and motor starters were controlled via Profinet. They transmitted status data using the communication protocol UDP on the same bus line with lower priority – without interfering with the control communication.

“Coming from the gear units, all data regarding current consumption, speed, voltage and the status word are tunnelled via a Siemens PLC and then transmitted to an IoT gateway and into the Cloud,” says Jörg Niermann from NORD. As a consequence, fault conditions and overloads of the drives can be visualised and detected. In addition, status data can be evaluated for energy management and remote maintenance. “Virtual sensors – this means pre-processing of internal status data – enable determination of oil temperature and oil ageing for predictive maintenance without sensors. NORD is currently working on solutions for status monitoring with virtual sensors. For this, we use our own application test area,” Niermann explains.