Corrosion Protection

Optimal protection for demanding environments

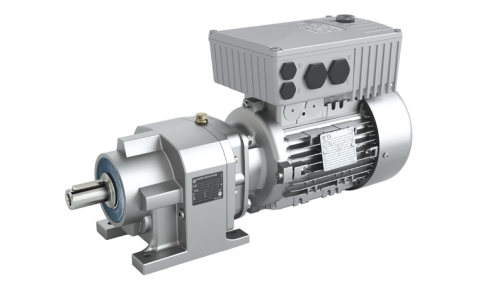

nsd tupH™ is our solution for corrosive ambient conditions. Benefit from the variety of our aluminium gear units, motors and frequency inverters in many fields, e.g. food, chemical, pharmaceutical and marine industries.

Great demands

Cleaning procedures with highly effective wash down agents are constantly being extended and place higher and higher demands on hygienic design and corrosion resistance.

According to the standards for the food, chemical and pharmaceutical industry, intensive, strict wash down and disinfection processes are required.

To prevent cleaning and disinfection agents deteriorating the material, design and coating of machines for such applications have to be smooth and ensure optimum cleanability for manual or automated cleaning cycles.

Geared motors and frequency inverters with smooth surface and nsd tupH surface treatment meet the demands on wear resistance and cleanability.

NORD DRIVESYSTEMS introduced new solutions (regarding materials, treatment and machining) for the surfaces of motors, gear units, and components and offers an endurance kit providing an enormous degree of resistance against acids and alkalis typically used for cleaning in the food, chemical and pharmaceutical industries.

Sealed Surface Conversion System

nsd tupH from NORD DRIVESYSTEMS is the perfect solution for high performance applications and extreme conditions. It is an alternative to multiple coats of paint and stainless steel in highly corrosive environments.

- Complies with FDA Title 21 DCFR 175.300

- Easy to clean surfaces

- Resistant to acids and alkalis (wide pH range)

- No spreading of corrosion, even after damage

- No flaking

- Corrosion-resistant - prevents contact corrosion

- Free from chromates

This is how it works

While traditional methods use only a superficial coat of paint and may even cover porous areas, the nsd tupH process has a base coat that permanently penetrates the surface of the aluminium, providing a strong base for the surface coating to bond. This combination offers extreme resistance and results in a surface harder than that of an untreated aluminium alloy.

Modern gear units must be robust, compact, powerful, economical and lightweight. The advantage of aluminium is its low weight because weight is a cost factor, especially if the gear unit itself is a load that has to be moved as part of an automated positioning system. For this reason, aluminium alloy has become the preferred material for gear unit housings in many fields.

NORD DRIVESYSTEMS improves many of the optimum properties that an aluminium alloy offers for NORD gear unit housings. The material also has some inherent corrosion resistance and does not need to be additionally protected in all cases. At the very least, aluminium housings conduct heat more efficiently than cast iron. The resulting low operating temperatures have an advantageous effect on the internal gear unit construction and allow a longer service life.

Referenced product #1542 doesn't have a SKU!

노드블럭.1 헬리컬 기어드모터

UNIVERSAL SMI 윔 기어 유닛

낮은 소음 및 매끄러움

동기 스무스 바디 모터

동기 모터

유니케이스 페러렐 샤프트 기어드모터

슬림형, 강력한 성능

NORDAC FLEX - SK 200E - 인버터

효율성 향상, 비용 절감

Krijn Verwijs

부식 방지 드라이브 시스템은 염분이 많은 환경에서 안정적으로 작동합니다.

갑각류 가공은 습하고 짠 분위기의 북해 해안 바로 근처에있는 네덜란드 가족 소유 회사 인 Krijn Verwijs B.V.에서 이루어집니다. 이것은 오랫동안 드라이브의 문제였습니다. NORD 표면 처리 nsd tupH는 안정적으로 작동합니다.

Ambit Projects

식품 산업을위한 다목적 드라이브 시스템

영국의 기계 제조업체 인 Ambit Projects는 농산물 세척 공장에 NORD 구동 시스템을 갖추고 있습니다. 표면 처리 nsd tupH는 부식으로부터 하우징을 최적으로 보호합니다.

MOPOS

박스 맥아 공장의 선삭 기계를위한 최신 세대 드라이브

다양한 맛의 뉘앙스를 개발하려면 복잡한 생산 공정이 필요합니다. 기계는 지속적으로 작동합니다. 고장을 방지하기 위해 MOPOS는 안정적인 NORD 드라이브를 설치합니다.

Octopi Brewery

양조장에서 사용되는 드라이브 시스템

Octopi Brewing (미국)의 경우 NORD DRIVESYSTEMS는 조빙 양조장의 요구 사항을 준수하는 특수 표면 처리 된 드라이브를 제공했습니다. nsd tupH 표면 처리를 통해 이러한 드라이브는 특히 부식에 대한 내성이 생겼습니다.