Corrosion Protection

Optimal protection for demanding environments

nsd tupH™ is our solution for corrosive ambient conditions. Benefit from the variety of our aluminium gear units, motors and frequency inverters in many fields, e.g. food, chemical, pharmaceutical and marine industries.

Great demands

Cleaning procedures with highly effective wash down agents are constantly being extended and place higher and higher demands on hygienic design and corrosion resistance.

According to the standards for the food, chemical and pharmaceutical industry, intensive, strict wash down and disinfection processes are required.

To prevent cleaning and disinfection agents deteriorating the material, design and coating of machines for such applications have to be smooth and ensure optimum cleanability for manual or automated cleaning cycles.

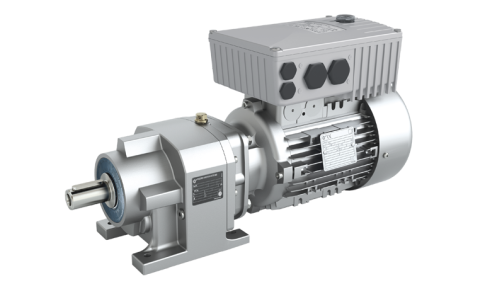

Geared motors and frequency inverters with smooth surface and nsd tupH surface treatment meet the demands on wear resistance and cleanability.

NORD DRIVESYSTEMS introduced new solutions (regarding materials, treatment and machining) for the surfaces of motors, gear units, and components and offers an endurance kit providing an enormous degree of resistance against acids and alkalis typically used for cleaning in the food, chemical and pharmaceutical industries.

Sealed Surface Conversion System

nsd tupH from NORD DRIVESYSTEMS is the perfect solution for high performance applications and extreme conditions. It is an alternative to multiple coats of paint and stainless steel in highly corrosive environments.

- Complies with FDA Title 21 DCFR 175.300

- Easy to clean surfaces

- Resistant to acids and alkalis (wide pH range)

- No spreading of corrosion, even after damage

- No flaking

- Corrosion-resistant - prevents contact corrosion

- Free from chromates

This is how it works

While traditional methods use only a superficial coat of paint and may even cover porous areas, the nsd tupH process has a base coat that permanently penetrates the surface of the aluminium, providing a strong base for the surface coating to bond. This combination offers extreme resistance and results in a surface harder than that of an untreated aluminium alloy.

Modern gear units must be robust, compact, powerful, economical and lightweight. The advantage of aluminium is its low weight because weight is a cost factor, especially if the gear unit itself is a load that has to be moved as part of an automated positioning system. For this reason, aluminium alloy has become the preferred material for gear unit housings in many fields.

NORD DRIVESYSTEMS improves many of the optimum properties that an aluminium alloy offers for NORD gear unit housings. The material also has some inherent corrosion resistance and does not need to be additionally protected in all cases. At the very least, aluminium housings conduct heat more efficiently than cast iron. The resulting low operating temperatures have an advantageous effect on the internal gear unit construction and allow a longer service life.

Referenced product #1542 doesn't have a SKU!

Redutor de engrenagens helicoidais NORDBLOC .1

Redutor sem-fim helicoidal UNIVERSAL SMI

Silencioso e liso

Motores lisos síncronos

Motores Síncronos

Motorredutores planos BLOCK

Finos e potentes

NORDAC LINK - SK 200E - Inversor de Frequência

Maior flexibilidade, menores custos

Krijn Verwijs

Os sistemas de acionamento resistentes à corrosão funcionam de forma confiável em ambientes salinos

O processamento de moluscos e crustáceos é realizado na empresa familiar holandesa Krijn Verwijs B.V., nas imediações da costa do Mar do Norte, num ambiente húmido e salino, o que tem sido um problema para as unidades. O tratamento de superfície NORD nsd tupH proporcionou alívio.

Ambit Projects

Sistemas de acionamento versáteis para a indústria alimentar

O construtor de máquinas inglês Ambit Projects equipa as suas instalações de lavagem de produtos agrícolas com sistemas de acionamento NORD. O tratamento de superfície nsd tupH fornece a proteção ideal contra a corrosão.

MOPOS

A última geração de acionamentos para máquinas da indústria de malte

Um complexo processo de produção é necessário para desenvolver diferentes nuances de sabor. uma vez que as máquinas funcionam em operação contínua, para evitar quebras, a MOPOS instala acionamentos NORD confiáveis.

Cervejaria Octopi

NORD no controle das torneiras

Para a Octopi Brewing dos EUA, a NORD DRIVESYSTEMS forneceu acionamentos com acabamento superficial especial, atendendo aos requisitos da cervejaria contratada. Com o tratamento de superfície nsd tupH, os equipamentos tornam-se particularmente resistentes à corrosão.